Lexus GS300/400 (2000 year). Manual - part 139

EM0DD–03

A02689

SST

A02688

Bushing bore diameter

mm (in.)

10.985 – 11.006 mm

(0.4325 – 0.4333 in.)

11.035 – 11.056 mm

(0.4344 – 0.4353 in.)

Both intake and exhaust

Bushing

size

Use STD

Use O/S

0.05

A02744

SST

P04791

Intake

Exhaust

38.5 mm

(1.516 in.)

40.5 mm

(1.594 in.)

EM–48

–

ENGINE MECHANICAL (2JZ–GE)

CYLINDER HEAD

1402

REPLACEMENT

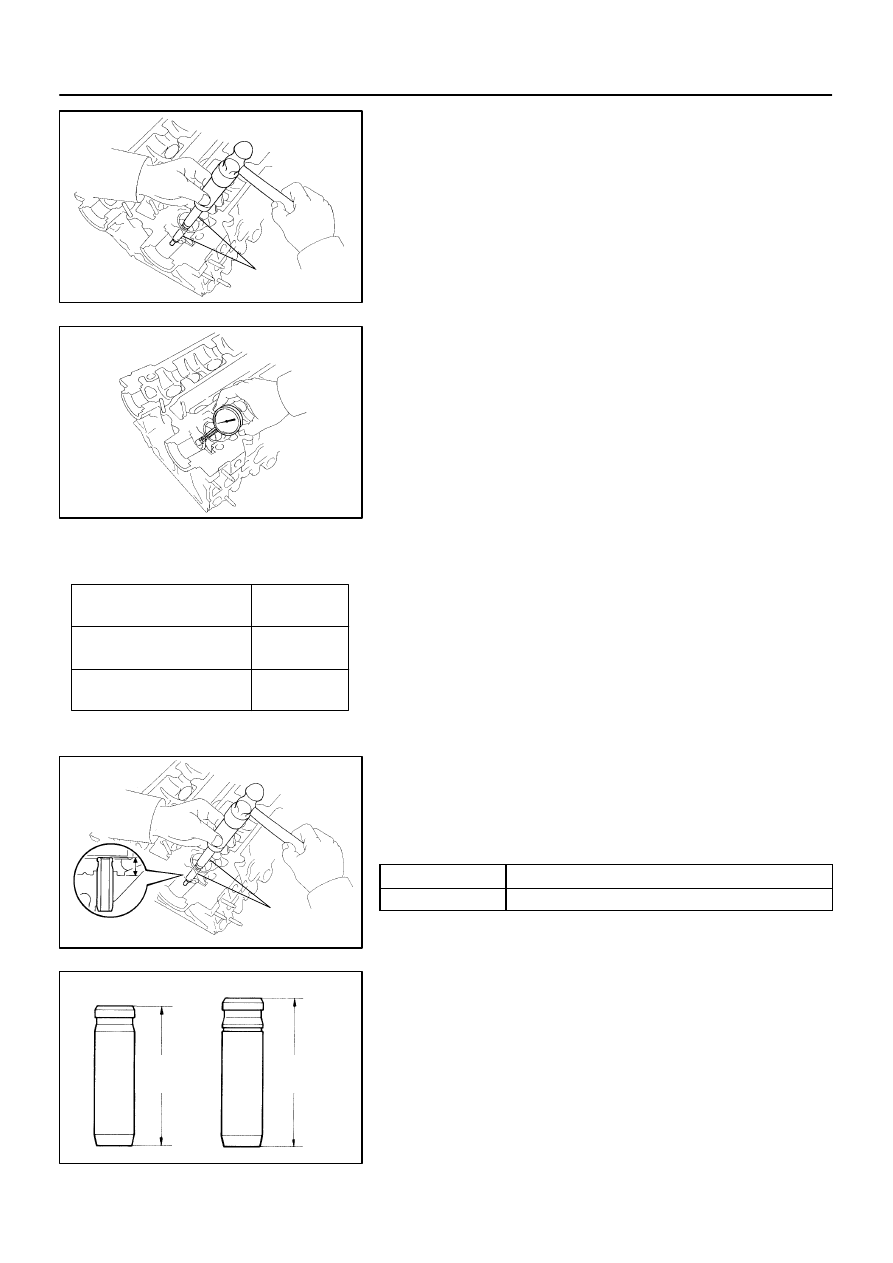

REPLACE VALVE GUIDE BUSHINGS

(a)

Using SST and a hammer, tap out the guide bushing.

SST

09201–10000 (09201–01060),

09950–70010 (09951–07100)

(b)

Using a caliper gauge, measure the bushing bore diame-

ter of the cylinder head.

(c)

Select a new guide bushing (STD or O/S 0.05).

If the bushing bore diameter of the cylinder head is greater than

11.006 mm (0.4333 in.), machine the bushing bore to the follow-

ing dimension:

11.035 – 11.056 mm (0.4344 – 0.4353 in.)

If the bushing bore diameter of the cylinder head is greater than

11.056 mm (0.4353 in.), replace the cylinder head.

(d)

Using SST and a hammer, tap in a new guide bushing to

the specified protrusion height.

SST

09201–10000 (09201–01060),

09950–70010 (09951–07100)

Protrusion height:

Intake

12.3 – 12.7 mm (0.484 – 0.500 in.)

Exhaust

11.4 – 11.8 mm (0.449 – 0.465 in.)

HINT:

Different bushings are used for the intake and exhaust.